Showing 1–12 of 15 results

Blast Hole Drilling

High Perfomance, Simple Maintenance Electrical Driven

EUROAIR Diesel Portable Compressor

Latest Screw Element Technology

The asymmetric rotors allow for increased efficiency. In addition, a low rotor speed and few moving parts minimize wear and tear for reliable performance and a long service life.

Clean Intake Air

A high performance two-stage air intage filter prevents dust and dirt particles from entering the engine and compressor. A service indicator on the filter tells you when it needs replacing.

Reputable Engine Brands

Every model has a carefully selected engine from a well-know and respected partner. All componets are protected inside the corrosion treated weatherproof hood

Efficient Fuel Filter

High – efficiency multi-step fuel filtration with water separator isolates and traps contaminants

Large Cooling Surface

Allowing optimal, intense use in hightemperature environments, wih working temperature up to 50C.

Fully Automatic Step-Less Speed Regulator

The in-house design controller together with the regulating system controls the engine speed to meet all customer’s needs, while keeping fuel consumption low.

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Pantented Powerxpert

The XC2003 controller features a very fast response curve, PowerXpert can instantly increase the rpm of the engine to achieve the maximum flow, while regulating the engine power curve at any specific pressure to allow more flow, faster flushing and increased drilling capacity.

Large Cooling Surface

Allowing optimal, intense use in high-temperature environments, with working temperatures up to 50C.

Depandable Gear Driven

Providing high transmission efficiency. Also minimizes any issues with the axles not aligning.

Heavy Duty Motor

The motor implements IEC standard, under protection class IP54. Making it suitable for high dust, non-stop working conditions

Union Control

Thanks to the CS6000 controller, customers can easily parallel two to six compressors to work together in harmony. This provides much greater flow and minimizes the effect of pressure drop.

Clean Intake Air

A high performance two-stage air intake filter prevents dust and dirt particles from entering the compressor. A service indicator on the filter tells you when it needs replacing.

Smart Control System

The CS6000 controllers have LCD display, good stability, and providing the full control of machine; multiplied languages selection.

Flexiable Coupling

The KTR coupling with elastic spider effectively reduces the effects of vibration and ensures higher reliability

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Technical Data

EUROAIR Diesel Portable Compressor

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | |||||

|---|---|---|---|---|---|

| MODEL | EUY050-7 | EUY085-14 | EUY100-10 | EUY100-12 | EUY120-7 |

| Working Pressure, bar ( psi ) | 7 (100) | 14 (205) | 10 (150) | 12 (175) | 7 (100) |

| Flow, I/s | cfm | m3/min | 83|177|5 | 142|300|8.5 | 167|353|10 | 167|353|10 | 200|424|12 |

| Noise Sound Level ( at 7m distance , dBA ) | 70+3 | 81+3 | 81+3 | 81+3 | 81+3 |

| Fuel tank capacity ( L ) | 67 | 120 | 120 | 120 | 120 |

| Compressor Oil Capacity ( L ) | 8 | 26 | 26 | 26 | 26 |

| Outlet Valves ( qty x size ) | 3xG3/4 | 1xG3/4 1xG1 1/2 | |||

| Engine | |||||

| Engine Maker | Kubota | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | V1505T | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 |

| Engine Power ( Kw ) | 33 | 96 | 96 | 96 | 96 |

| Norminal Engine Speed ( rpm ) | 2950 | 2300 | 2300 | 2300 | 2300 |

| Unloading Engine Speed ( rpm ) | 1950 | 1400 | 1400 | 1400 | 1400 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | |||||

| Box Mounted | |||||

| Length ( mm ) | 1940 | 2350 | 2350 | 2350 | 2350 |

| Width ( mm ) | 1200 | 1300 | 1300 | 1300 | 1300 |

| Height ( mm ) | 1240 | 1550 | 1550 | 1550 | 1550 |

| Weight ( kg ) | 650 | 1470 | 1470 | 1470 | 1470 |

| With Undercarriage ( adjustable tow bar horizontally ) | |||||

| Length ( mm ) | 2960 | 3700 | 3700 | 3700 | 3700 |

| Width ( mm ) | 1350 | 1790 | 1790 | 1790 | 1790 |

| Height ( mm ) | 1420 | 1900 | 1900 | 1900 | 1900 |

| Weight ( kg ) | 750 | 1650 | 1650 | 1650 | 1650 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY120-14 | EUY150-15 | EUY160-17 | EUY200-10 | EUY220-8* | EUY180-19 | EUY310-25 | EUY390-25* | EUY390-30 | EUY340-34 |

| Working Pressure, bar ( psi ) | 14 (205) | 15 (220) | 17 (250) | 10/17 (150/250) | 8/10 (115/150) | 19 (275) | 25.....18 (360.....260) |

25.....15 (360.....220) |

30.....20 (435.....290) |

34.....20 (493.....290) |

| Flow, I/s | cfm | m3/min | 200|424|12 | 250|530|15 | 267|565|16 | (333|706|20)/ (267|565|16) |

(367|777|22)/ (333|706|20) |

300|635|18 | (467|988|28) (517|1094|31) |

(583|1235|35) (650|1377|39) |

(583|1235|35) (650|1377|39) |

(533|1130|32) (567|1200|34) |

| Noise Sound Level ( at 7m distance , dBA ) | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 |

| Fuel tank capacity ( L ) | 180 | 250 | 250 | 250 | 250 | 300 | 500 | 550 | 710 | 710 |

| Compressor Oil Capacity ( L ) | 23 | 32 | 32 | 32 | 55 | 55 | 75 | 105 | 105 | 105 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/3 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Engine | ||||||||||

| Engine Maker | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | YC6J175-H301 | YC6A205-H300 | YC6A240-H301 | YC6A240-H301 | YC6A240-H301 | YC6A260-H300 | YC6MK400-H300 | YC6K510-KT30 | YC6K560-KT30 | YC6K560-KT30 |

| Engine Power ( Kw ) | 129 | 151 | 176 | 176 | 176 | 191 | 295 | 375 | 412 | 412 |

| Norminal Engine Speed ( rpm ) | 2300 | 2050 | 1950 | 2100/1800 | 2100/1800 | 1900 | 1750.....1900 | 1500.....1750 | 1500.....1750 | 1600.....1750 |

| Unloading Engine Speed ( rpm ) | 1400 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 2680 | 2680 | 2680 | 2680 | 2880 | 3985 | 4336 | 4336 | 4336 |

| Width ( mm ) | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 | 1800 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1637 | 1637 | 1637 | 1920 | 1920 | 1920 | 2200 | 2290 | 2290 | 2290 |

| Weight ( kg ) | 2050 | 2350 | 2350 | 2380 | 2380 | 3000 | 4550 | 4770 | 4770 | 4770 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4322 | 4322 | 4322 | 4322 | 4322 | 4341 | 5260 | 5590 | 5590 | 5590 |

| Width ( mm ) | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 | 2040 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1980 | 1980 | 1980 | 2270 | 2270 | 2270 | 2630 | 2660 | 2660 | 2660 |

| Weight ( kg ) | 2250 | 2550 | 2550 | 2685 | 2685 | 3330 | 5150 | 5270 | 5270 | 5270 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY100D-7 | EUY120D-13 | EUY130D-7 | EUY130D-10 | EUY165D-10 | EUY13D-13 | EUY203D-7 | EUY230D-8 | EUY210D-10 | EUY165D-14 |

| Working Pressure, bar ( psi ) | 7 (100) | 13 (185) | 7 (100) | 10 (150) | 10 (150) | 13 (185) | 7 (100) | 8 (115) | 10 (150) | 14 (205) |

| Flow, I/s | cfm | m3/min | 167|353|10 | 183|388|11 | 217|459|13 | 217|459|13 | 275|582|16.5 | 225|477|13.5 | 338|717|20.5 | 383|812|23 | 350|741|21 | 275|582|16.5 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 |

| Compressor Oil Capacity ( L ) | 20 | 28 | 28 | 28 | 55 | 55 | 55 | 55 | 55 | 55 |

| Outlet Valves ( qty x size ) | 1xG1 1/2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 55 | 90 | 75 | 90 | 110 | 110 | 110 | 132 | 132 | 132 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.9 | 0.88 | 0.9 | 0.88 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2235 | 2200 | 2200 | 2200 | 2680 | 2680 | 2680 | 2680 | 2680 | 2680 |

| Width ( mm ) | 1300 | 1170 | 1170 | 1170 | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 |

| Height ( mm ) | 1623 | 1400 | 1400 | 1400 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Weight ( kg ) | 1520 | 1440 | 1340 | 1440 | 2285 | 2285 | 2285 | 2285 | 2285 | 2285 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 3651 | 3840 | 3840 | 3840 | 4232 | 4232 | 4232 | 4232 | 4232 | 4232 |

| Width ( mm ) | 1790 | 1680 | 1680 | 1680 | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 |

| Height ( mm ) | 1850 | 1740 | 1740 | 1740 | 2170 | 2170 | 2170 | 2170 | 2170 | 2170 |

| Weight ( kg ) | 1700 | 1640 | 1540 | 1640 | 2590 | 2590 | 2590 | 2590 | 2590 | 2590 |

| MODEL | EUY150D-16 | EUY170D-17 | EUY250D-10 | EUY210D-14 | EUY280D-8.5 | EUY280D-10 | EUY238D-14 | EUY220D-21 | EUY250D-21 | EUY290D-21 |

|---|---|---|---|---|---|---|---|---|---|---|

| Working Pressure, bar ( psi ) | 16 (230) | 17 (250) | 10 (150) | 14 (205) | 8.5 (125) | 10 ( 150) | 14 (205) | 21 (305) | 22 (305) | 23 (305) |

| Flow, I/s | cfm | m3/min | 250|530|15 | 283|600|17 | 417|883|25 | 350|741|21 | 467|988|28 | 467|988|28 | 397|840|23.5 | 367|777|22 | 417|883|25 | 483|1024|29 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 78+3 | 78+3 | 78+3 |

| Compressor Oil Capacity ( L ) | 55 | 61 | 65 | 65 | 65 | 65 | 65 | 92 | 92 | 92 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 132 | 160 | 160 | 160 | 160 | 180 | 180 | 200 | 220 | 250 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.9 | 0.9 | 0.9 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 3280 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 |

| Width ( mm ) | 1660 | 1670 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Height ( mm ) | 1800 | 1870 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 |

| Weight ( kg ) | 2285 | 2850 | 3900 | 3900 | 3900 | 4000 | 4000 | 4100 | 4250 | 4300 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4232 | 4550 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 |

| Width ( mm ) | 1950 | 1770 | 1800 | 1800 | 1800 | 1800 | 1800 | 2040 | 2040 | 2040 |

| Height ( mm ) | 2170 | 2230 | 2590 | 2590 | 2590 | 2590 | 2590 | 2630 | 2630 | 2630 |

| Weight ( kg ) | 2590 | 2460 | 4500 | 4500 | 4500 | 4600 | 4600 | 4700 | 4850 | 4900 |

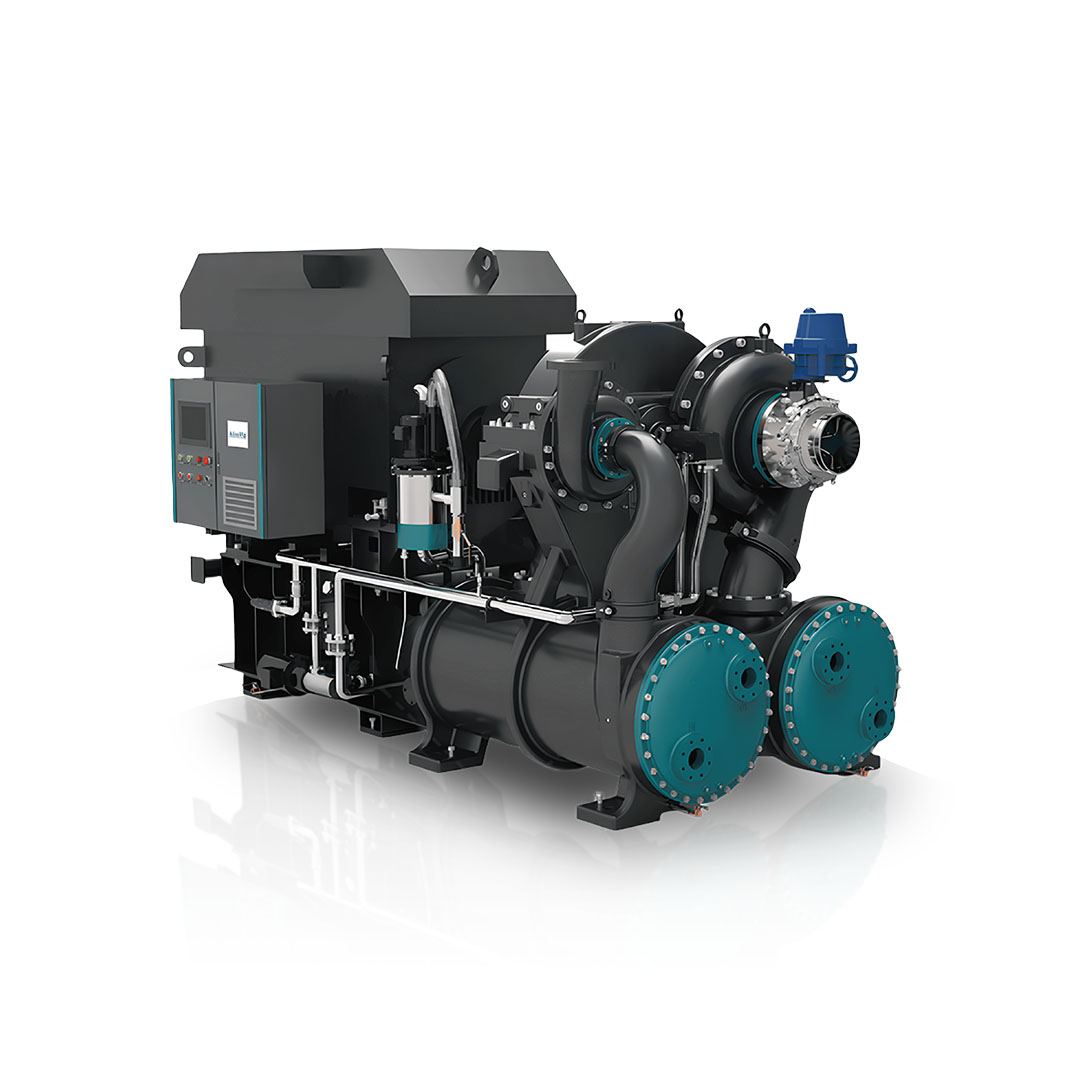

Centrifugal Air Compressor

Feature And Advantages

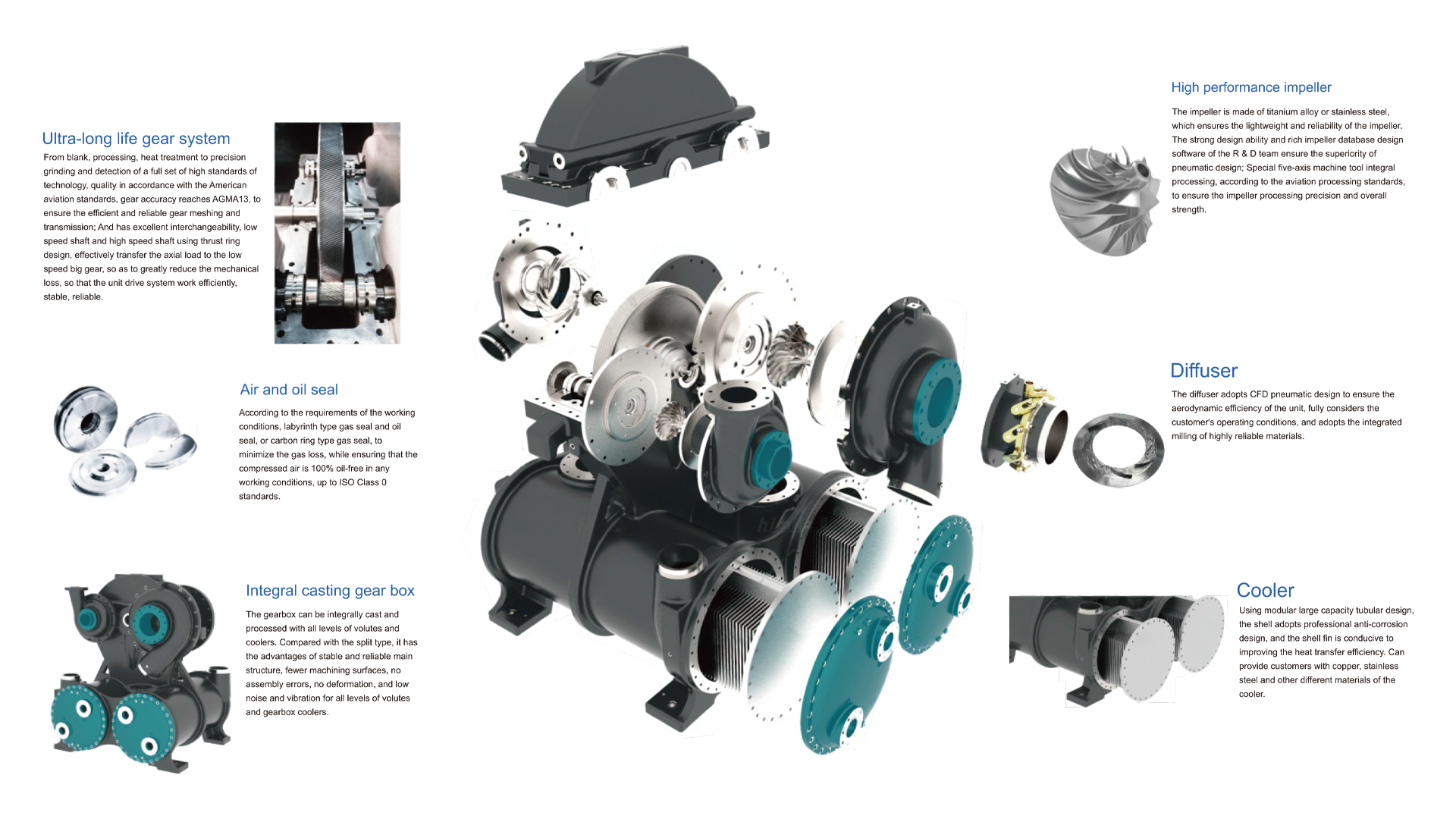

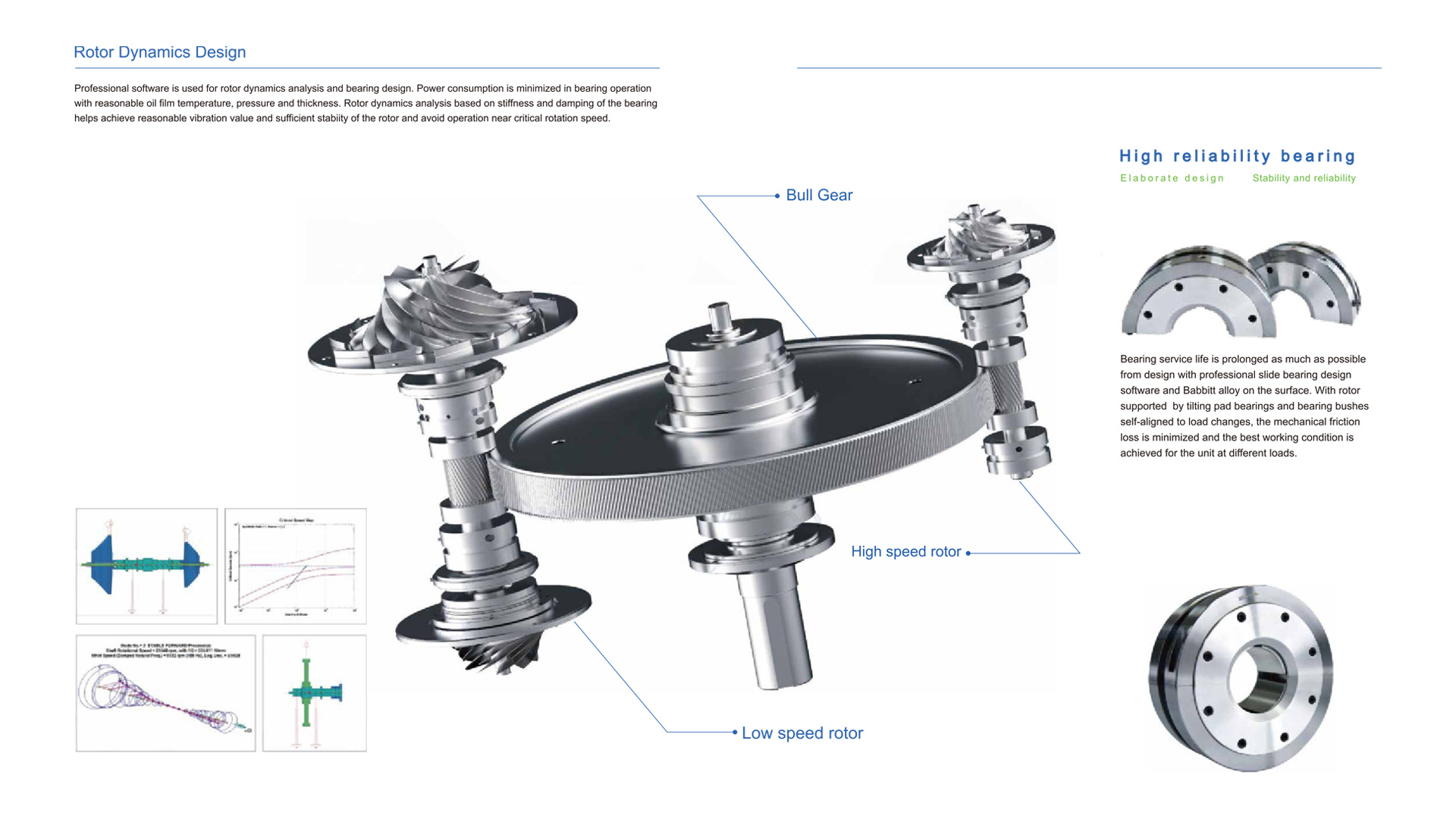

EUROAIR Centrifugal Compressor Product Feature

Main Structure

Technical Parameter

Technical Parameters Of Centrifugal Compressor ( Air/Nitrogen )

| Model | Pressure | Flow Range | Motor Power | Overal Dimension | Weight | ||

|---|---|---|---|---|---|---|---|

| Barg | kW | kW | L (mm) | W (mm) | H (mm) | kg | |

| HM6000 | 1.2-16 | 55-100 | 250-450 | 3600 | 1800 | 1900 | 8200 |

| HM7200 | 1.2-16 | 95-200 | 315-1200 | 3900 | 2000 | 2250 | 10300 |

| HM12000 | 1.2-16 | 118-225 | 350-1500 | 4300 | 2000 | 2300 | 11100 |

| HM15000 | 1.2-16 | 200-310 | 550-1800 | 4350 | 2100 | 2700 | 12500 |

| HM20000 | 1.2-16 | 280-425 | 710-2500 | 5200 | 2400 | 3300 | 17500 |

Technical Parameters Of Centrifugal Compressor ( Air/Nitrogen )

| Model | Pressure | Flow Range | Motor Power | Overal Dimension | Weight | ||

|---|---|---|---|---|---|---|---|

| Barg | kW | kW | L (mm) | W (mm) | H (mm) | kg | |

| HM30000 | 1.2-25 | 410-700 | 1100-4000 | 7500 | 2600 | 3100 | 27000 |

| HM50000 | 1.2-25 | 620-1000 | 1700-5500 | 8100 | 4000 | 3700 | 38000 |

| HM72000 | 1.2-30 | 800-1600 | 2200-9000 | 12000 | 5000 | 5300 | 65000 |

| HM100000 | 1.2-10 | 1000-2000 | 2800-11000 | 15000 | 6200 | 6000 | 80000 |

Technical Parameters of air separation Centrifugal Compressor ( Turbo Charger )

| Model | Pressure | Flow Range | Exhaust Pressure | Motor Power | Overal Dimension | Weight | ||

|---|---|---|---|---|---|---|---|---|

| Barg | kW | MPa | kW | L (mm) | W (mm) | H (mm) | kg | |

| HM4000-B | 0.3-1.0 | 347-550 | 1.6-5.0 | 1100-4000 | 7500 | 2600 | 3100 | 27000 |

| HM6500-B | 0.3-1.0 | 530-920 | 1.6-5.0 | 1700-5500 | 8100 | 4000 | 3700 | 38000 |

| HM10000-B | 0.3-1.0 | 830-1660 | 1.6-5.0 | 2200-9000 | 12000 | 5000 | 5300 | 65000 |

| HM20000-B | 0.3-1.0 | 1780-3000 | 1.6-5.0 | 2800-11000 | 15000 | 6200 | 6000 | 80000 |

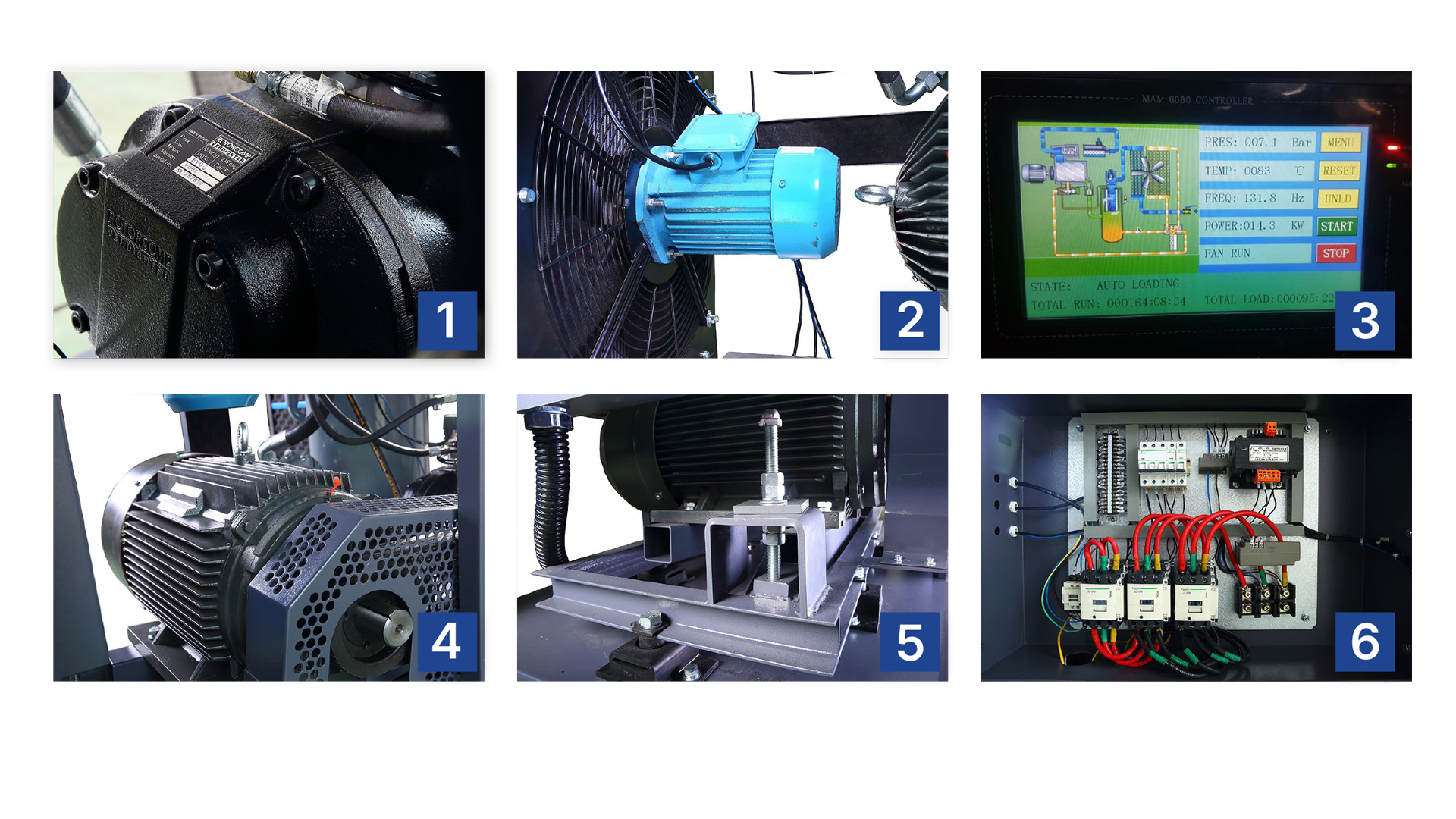

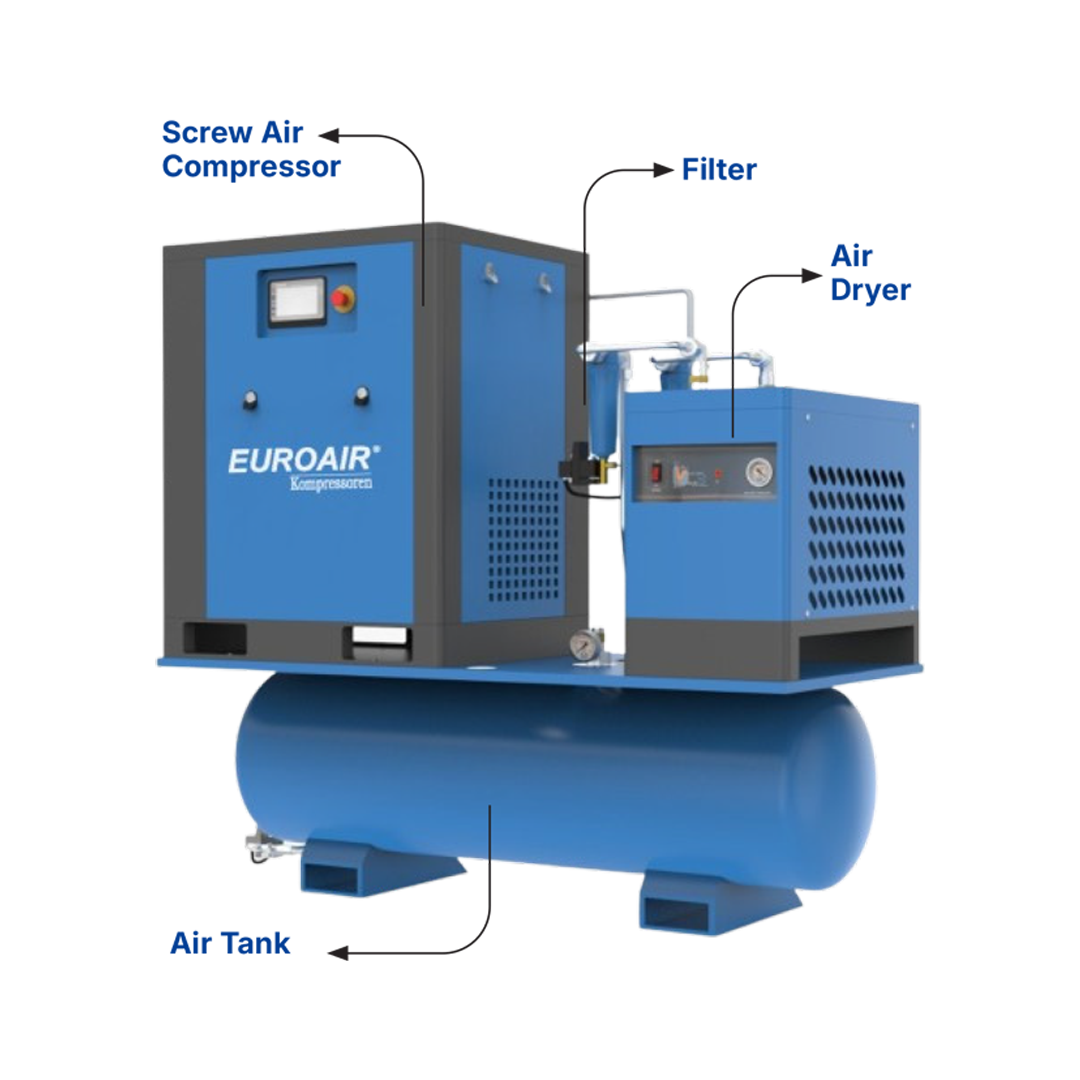

Compacted Screw Compressor

Feature And Advantages

EUROAIR Compacted Screw Compressor

- Screw air end from world’s manufacturer – Rotorcomp

- Excellent cooling system, the heat dissipantion is increased by 20 – 30% in comparison with conventional versions

- Advanced intelligent control system with color touch screen, making operation easier

- Equipped with energy saving electric motor (SF=1.2, IP55, IE3 CE&MEPS), Increasing 15% efficiency

- Schneider electrical components are used, enabling the screw air compressor to be used in harsh environment with reliable operation

- Pantented OPTI belt transmission, the belt is tensioned through the action of starting torque and mtor weight. The design service life can reach 25000 hours and transmission efficiency is 98% and above; to ensure reliable operation under high – temperature conditions.

Technical Data

EUROAIR Compcated Screw Compressor

| TECHNICAL PARAMETERS OF COMPACTED SCREW COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ITEM | UNIT | MODEL | ||||||||

| EAC-5.5/16 | EAC-7.5/16 | EAC-11/16 | EAC-15/16 | EAC-18.5/16 | EAC-22/16 | EAC-30/16 | EAC-37/16 | |||

| Compressor | ||||||||||

| Capacity (f.a.d) at gauged pressure | m3/min | 0,3 | 0,5 | 0,8 | 1 | 1,5 | 1,6 | 2,7 | 3,4 | |

| cfm | 10,59 | 17,65 | 28,25 | 35,31 | 52,97 | 56,5 | 95,34 | 120,06 | ||

| Max. Working Pressure | Bar / Mpa | 16 / 1,6 | ||||||||

| Compresor Type | Oil Inject Screw Compressor | |||||||||

| Cooling Type | Air Cooling | |||||||||

| Driven Type | Belt driven / Direct Driven | |||||||||

| Inlet Status | Temperature | C | < 45 | |||||||

| Pressure | Mpa | Atmospheric pressure | ||||||||

| Relative Humidity | <90% | |||||||||

| Cooling air flow | m3/hr | 4800 | 4800 | 5300 | 5300 | 7200 | 7800 | 9200 | 9200 | |

| Control Mode | Intelligent Controller | |||||||||

| Safety Valve Set Pressure | Mpa | 1,76 | ||||||||

| Lubricating oil volume | L | 10 | 15 | 20 | ||||||

| Lubricating oil brand | ROTORCOMP | |||||||||

| Drive rotor speed | rpm | 2900 | 2930 | 2940 | ||||||

| Main Motor | Rated Power | kW | 5,5 | 7,5 | 11 | 15 | 18,5 | 22 | 30 | 37 |

| HP | 7,5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | ||

| Type | Fix Speed | |||||||||

| Speed | rpm | 2900 | 2930 | 2940 | ||||||

| Service Factor | 1,2 | |||||||||

| Protection Type | IP55 | |||||||||

| Insulation class | ISO | F | ||||||||

| Efficiency | IE3 | |||||||||

| Startup Mode | Direct Starting | |||||||||

| Voltage ( Special on request ) | V | 380 | ||||||||

| Frequency ( Special on request ) | Hz | 50 | ||||||||

| Rated Current | A | 10,5 | 14,37 | 20,59 | 27,86 | 34,18 | 40,52 | 54,89 | 67,41 | |

| Fan Motor | Rated Power | kW | 0,12 | 0,12 | 0,37 | 0,37 | 0,55 | 0,55 | 0,55 | 1,5 |

| Type | Fix Speed | |||||||||

| Speed | rpm | 1400 | ||||||||

| Protection Type | IP55 | |||||||||

| Insulation class | ISO | F | ||||||||

| Startup Mode | Direct Starting | |||||||||

| Voltage (Special on request) | V | 380 | ||||||||

| Frequency ( Special on request ) | Hz | 50 | ||||||||

| ITEM | UNIT | MODEL | |||||||

|---|---|---|---|---|---|---|---|---|---|

| EAC-5.5/16 | EAC-7.5/16 | EAC-11/16 | EAC-15/16 | EAC-18.5/16 | EAC-22/16 | EAC-30/16 | EAC-37/16 | ||

| Dryer | |||||||||

| Capacity | m3/min | 1,5 | 2,4 | 3,8 | 6,5 | ||||

| Working Pressure | Mpa | 0.5-1.6 | |||||||

| Power | Kw | 0,65 | 0,75 | 1 | 1,5 | ||||

| Pressure Drew Point | C | 2-10 | |||||||

| Inlet Temp | C | <80 | |||||||

| Weight | Kg | 80 | |||||||

| Power (Special on request) | Vac/ Ph/Hz |

220/1/150 | 220/1/50 | 220/150 | 220/1/50 | ||||

| Piping Filters | |||||||||

| Capacity | m3/ min |

1,5 | 2,4 | 3,8 | 6 | ||||

| Particales Content (afer 3 degree filteration) | 0,01 | ||||||||

| Residual oil content (after 3 degree filteration) | ppm | 0,01 | |||||||

| Air Tank | |||||||||

| Volume | L | 160 | 270 | 400 | 500 | ||||

| Others | |||||||||

| Section of electric cable | mm | 5 x 6 | 5 x 6 | 5 x 10 | 5 x 10 | 5 x 16 | 5 x 16 | 4 x 25 | 5 x 35 |

| Recom HRC fuse | A | 35 | 35 | 50 | 50 | 63 | 63 | 80 | 100 |

| Sound Level | dB(A) | <70 | <70 | <71 | <73 | <74 | <74 | <75 | <70 |

| Compressed air outlet connection | G3/4 | G3/4 | G1 | G1 | G1 | G1 | G1-1/2 | G1-1/2 | |

| Dimension ( L x W x H ) | mm | 1250x650x1600 | 1250x650x1600 | 2000x800x1600 | 2000x800x1600 | 2100x950x1650 | 2100x950x1650 | 2150x1000x1750 | 2200x1060x1850 |

| Net Weight | kg | 270 | 290 | 350 | 370 | 415 | 470 | 715 | 785 |

EXTERNALLY HEATED PURGE DESICCANT AIR DRYER

Product Advantages

-

Automatic Control System

Automatic control system and alarm device, ensure the safety and reliability.

-

Air Controlling Dust Filter

Air controlling dust filter prevents the dust from air controlling components, lower the valves failure rate.

-

Silencer

New design silencer is made from heat-resistant hyperfine sound-absorbing glass, the noise level ≤72dB(A)

-

Stainless Steel Disperser

Stainless steel disperser stabilizes, disperses and filters the air flow.

-

High Quality Desiccant

High quality desiccant activated aluminum or molecular sieve, long service life.

Technical Specifications

EUROAIR Externally Heated Purge Dessicant Air Dryer

| EXTERNALLY HEATED PURGE DESICCANT AIR DRYER | |||||||

|---|---|---|---|---|---|---|---|

| Type | Capacity ( Nm3/min ) |

Heater Power (kW) |

Air Inlet/Outlet Pipa Diameter |

Dimension | Weight (kg) |

||

| L | W | H | |||||

| HDR-10XF | 1.2 | 1.5 | ZG1 | 800 | 480 | 1420 | 145 |

| HDR-20XF | 2.4 | 1.5 | ZG1 | 800 | 480 | 1520 | 200 |

| HDR-30XF | 3.8 | 1.5 | ZG1.5 | 1000 | 525 | 1600 | 330 |

| HDR-50XF | 5.5 | 1.5 | ZG1.5 | 1000 | 525 | 1890 | 350 |

| HDR-60XF | 6.5 | 3 | ZG1.5 | 1200 | 550 | 1950 | 430 |

| HDR-75XF | 8.5 | 3 | ZG1.5 | 1400 | 600 | 2000 | 550 |

| HDR-100XF | 10.7 | 4.5 | ZG2 | 1400 | 600 | 2090 | 750 |

| HDR-150XF | 13.5 | 4.5 | ZG2 | 1400 | 600 | 2140 | 790 |

| HDR-200XF | 18 | 4.5 | DN65 | 1400 | 650 | 2200 | 830 |

| HDR-250XF | 25 | 6 | DN80 | 1670 | 725 | 2435 | 1250 |

| HDR-300XF | 35 | 8 | DN100 | 1670 | 725 | 2566 | 1480 |

| HDR-350XF | 45 | 8 | DN100 | 1670 | 775 | 2700 | 1740 |

| HDR-400XF | 55 | 15 | DN125 | 1800 | 775 | 2755 | 2260 |

| HDR-450XF | 65 | 15 | DN125 | 1900 | 800 | 3070 | 2600 |

| HDR-500XF | 85 | 20 | DN150 | 2620 | 1120 | 3073 | 3380 |

| HDR-550XF | 110 | 30 | DN150 | 3100 | 1650 | 3200 | 4390 |

| HDR-600XF | 160 | 50 | DN200 | 3240 | 1770 | 3190 | 5800 |

Fixed Speed Driven Screw Compressor

Product Feature

State-of-the-art Compressor Airend

Optimal Energy efficiency and outstanding reliability is achieved from patented design third generation non-symmetric robust rotors, superior bearings and oil seal that help the compressor airend to operate with good dynamic balance, low vibration, low rotation speed and low noice level.

Reliable Automatic Control Box with Schneider Electrical Element

Electronic components of the IP55 automatic control box such as relays, contractors are from named brand – Schneider to provide safe and reliable comressor control solution. Advanced microprocessor based PLC controller is used to adjust compressor loading according to system air demand automatically. Versatile fault diagnosis and protection functions to assure stable and reliable operation of the compressor.

High Efficiency Intake Filter System

Intake air pre-filter and big surface air filter element can efficiently remove dust particles from intake cooling air and at the same time to maintain low noice level. Ventilating air is ducted in via special channel, cooler ambient air to be compressed will result high air delivery due to increase volumetric efficiency.

Intelligent Touch Screen Control Panel

The simple-to-use automatic electric control panel continously monitors and displays oberall system performance status with pro-active service indications, alarm for malfunctions, and safety shutdowns. Advance squance control for multi units installation and remote control as optio

Multi Stage Air/oil Separation System

The latest Europian patented multi-stage air/oil separation system to guarantee low residual oil content of less than 1-3 ppm. This exceeds ary international standard of oil injected rotary screw air compressor and is particularly suitable for customers with clean air for applications.

Feature And Advantages

Fixed Speed Air Compressor

State-of-the-art Compressor Airend

Optimal Energy efficiency and outstanding reliability is achieved from patented design third generation non-symmetric robust rotors, superior bearings and oil seal that help the compressor airend to operate with good dynamic balance, low vibration, low rotation speed and low noice level.

Intelligent Touch Screen Control Panel

The simple-to-use automatic electric control panel continously monitors and displays oberall system performance status with pro-active service indications, alarm for malfunctions, and safety shutdowns. Advance squance control for multi units installation and remote control as optio

Reliable Automatic Control Box with Schneider Electrical Element

Electronic components of the IP55 automatic control box such as relays, contractors are from named brand – Schneider to provide safe and reliable comressor control solution. Advanced microprocessor based PLC controller is used to adjust compressor loading according to system air demand automatically. Versatile fault diagnosis and protection functions to assure stable and reliable operation of the compressor.

High Efficiency Intake Filter System

Intake air pre-filter and big surface air filter element can efficiently remove dust particles from intake cooling air and at the same time to maintain low noice level. Ventilating air is ducted in via special channel, cooler ambient air to be compressed will result high air delivery due to increase volumetric efficiency.

Multi Stage Air/oil Separation System

The latest Europian patented multi-stage air/oil separation system to guarantee low residual oil content of less than 1-3 ppm. This exceeds ary international standard of oil injected rotary screw air compressor and is particularly suitable for customers with clean air for applications.

Technical Specification

| SMALL TO MEDIUM CAPACITY | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | EA-7.5D | EA-11D | EA-15D | EA-18.5D | EA-22D | EA-30D | EA-37D | EA-45D | |

| Flow Capacity Working Pressure (m³/min.Mpa) |

1.20/0.7 | 1.70/0.70 | 2.35/0.7 | 3.10/0.07 | 3.65/0.7 | 5.20/0.7 | 6.70/0.7 | 7.70/0.7 | |

| 1.15/07 | 1.65/0.8 | 2.30/0.8 | 3.00/0.8 | 3.60/0.8 | 5.00/0.8 | 6.30/0.8 | 7.60/0.8 | ||

| 1.00/1.0 | 1.50/1.0 | 2.05/1.0 | .2.60/1.0 | 3.20/1.0 | 4.50/2.0 | 5.80/1.0 | 7.00/1.0 | ||

| 0.75/1.3 | 1.15/1.3 | 1.65/1.3 | 2.10/1.3 | 2.75/1.3 | 3.70/1.3 | 4.80/1.3 | 5.80/1.3 | ||

| Electrical Motor |

Power (kW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 |

| Horse Power (HP) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | |

| Voltage ( V ) Frequency ( Hz ) |

380 / 50 | ||||||||

| Noise of the unit (dB(A)±3) |

70 | 70 | 70 | 72 | 72 | 72 | 72 | 72 | |

| Oil content in the air | ≤2 | ||||||||

| Exhaust Temperature | Ambient temperature +10°C / Cooling Water Temperature +10°C | ||||||||

| Exhaust Size | G3/4 | G3/4 | G1 | G1 | G1 | G½ | G½ | G½ | |

| Net Weight of the limit | 320 | 340 | 360 | 450 | 470 | 780 | 830 | 900 | |

| Overal Dimension | 800x700x930 | 1080x750x1000 | 1080x650x1000 | 1310x850x1160 | 1310x850x1160 | 1500x1000x1320 | 1500x1000x1320 | 1500x1000x1320 | |

| Medium To Big Capacity | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | EA-55D | EA-75D | EA-90D | EA-110D | EA-132D | EA-160D | EA-200D | EA-250D | |

Flow Capacity Working Pressure (m³/min.Mpa) |

10.8 / 0.7 | 13.6 / 0.7 | 17.00 / 0.7 | 24.50 / 0.7 | 24.50 / 0.7 | 29.20 / 0.7 | 37.50 / 0.7 | 46.50 / 0.7 | |

| 10.0 / 0.8 | 13.0 / 0.8 | 15.30 / 0.8 | 23.50 / 0.8 | 23.50 / 0.8 | 28.00 / 0.8 | 36.00 / 0.8 | 46.00 / 0.8 | ||

| 9.00 / 1.0 | 11.5 / 1.0 | 14.00 / 1.0 | 21.00 / 1.0 | 21.00 / 1.0 | 26.00 / 1.0 | 33.00 / 1.0 | 40.00 / 1.0 | ||

| 7.80 / 1.3 | 9.80 / 1.3 | 12.00 / 1.3 | 17.50 / 1.3 | 17.50 / 1.3 | 22.00 / 1.3 | 26.00 / 1.3 | 36.00 / 1.3 | ||

Electrical Motor |

Power (kW) | 55 | 75 | 90 | 110 | 132 | 160 | 200 | 250 |

| Horse Power (HP) | 75 | 100 | 125 | 150 | 180 | 220 | 270 | 340 | |

| Voltage ( V ) Frequency ( Hz ) |

380 / 50 | ||||||||

| Noise of the unit (dB(A)±3) |

76 | 76 | 76 | 79 | 79 | 79 | 79 | 79 | |

| Oil content in the air | ≤2 | ||||||||

| Exhaust Temperature | Ambient temperature +10°C / Cooling Water Temperature +10°C | ||||||||

| Exhaust Size | G2 | G2 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | |

| Net Weight of the limit | 1180 | 1340 | 1850 | 2200 | 2260 | 3300 | 3600 | 5700 | |

| Overal Dimension | 1750x1200x1500 | 1750x1200x1500 | 1750x1200x1500 | 2350x1500x1760 | 2350x1500x1760 | 2650x1650x1800 | 2650x1650x1800 | 3000x1950x1850 | |

General Construction

High Perfomance, Simple Maintenance Electrical Driven

EUROAIR Diesel Portable Compressor

Latest Screw Element Technology

The asymmetric rotors allow for increased efficiency. In addition, a low rotor speed and few moving parts minimize wear and tear for reliable performance and a long service life.

Clean Intake Air

A high performance two-stage air intage filter prevents dust and dirt particles from entering the engine and compressor. A service indicator on the filter tells you when it needs replacing.

Reputable Engine Brands

Every model has a carefully selected engine from a well-know and respected partner. All componets are protected inside the corrosion treated weatherproof hood

Efficient Fuel Filter

High – efficiency multi-step fuel filtration with water separator isolates and traps contaminants

Large Cooling Surface

Allowing optimal, intense use in hightemperature environments, wih working temperature up to 50C.

Fully Automatic Step-Less Speed Regulator

The in-house design controller together with the regulating system controls the engine speed to meet all customer’s needs, while keeping fuel consumption low.

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Pantented Powerxpert

The XC2003 controller features a very fast response curve, PowerXpert can instantly increase the rpm of the engine to achieve the maximum flow, while regulating the engine power curve at any specific pressure to allow more flow, faster flushing and increased drilling capacity.

Large Cooling Surface

Allowing optimal, intense use in high-temperature environments, with working temperatures up to 50C.

Depandable Gear Driven

Providing high transmission efficiency. Also minimizes any issues with the axles not aligning.

Heavy Duty Motor

The motor implements IEC standard, under protection class IP54. Making it suitable for high dust, non-stop working conditions

Union Control

Thanks to the CS6000 controller, customers can easily parallel two to six compressors to work together in harmony. This provides much greater flow and minimizes the effect of pressure drop.

Clean Intake Air

A high performance two-stage air intake filter prevents dust and dirt particles from entering the compressor. A service indicator on the filter tells you when it needs replacing.

Smart Control System

The CS6000 controllers have LCD display, good stability, and providing the full control of machine; multiplied languages selection.

Flexiable Coupling

The KTR coupling with elastic spider effectively reduces the effects of vibration and ensures higher reliability

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Technical Data

EUROAIR Diesel Portable Compressor

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | |||||

|---|---|---|---|---|---|

| MODEL | EUY050-7 | EUY085-14 | EUY100-10 | EUY100-12 | EUY120-7 |

| Working Pressure, bar ( psi ) | 7 (100) | 14 (205) | 10 (150) | 12 (175) | 7 (100) |

| Flow, I/s | cfm | m3/min | 83|177|5 | 142|300|8.5 | 167|353|10 | 167|353|10 | 200|424|12 |

| Noise Sound Level ( at 7m distance , dBA ) | 70+3 | 81+3 | 81+3 | 81+3 | 81+3 |

| Fuel tank capacity ( L ) | 67 | 120 | 120 | 120 | 120 |

| Compressor Oil Capacity ( L ) | 8 | 26 | 26 | 26 | 26 |

| Outlet Valves ( qty x size ) | 3xG3/4 | 1xG3/4 1xG1 1/2 | |||

| Engine | |||||

| Engine Maker | Kubota | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | V1505T | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 |

| Engine Power ( Kw ) | 33 | 96 | 96 | 96 | 96 |

| Norminal Engine Speed ( rpm ) | 2950 | 2300 | 2300 | 2300 | 2300 |

| Unloading Engine Speed ( rpm ) | 1950 | 1400 | 1400 | 1400 | 1400 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | |||||

| Box Mounted | |||||

| Length ( mm ) | 1940 | 2350 | 2350 | 2350 | 2350 |

| Width ( mm ) | 1200 | 1300 | 1300 | 1300 | 1300 |

| Height ( mm ) | 1240 | 1550 | 1550 | 1550 | 1550 |

| Weight ( kg ) | 650 | 1470 | 1470 | 1470 | 1470 |

| With Undercarriage ( adjustable tow bar horizontally ) | |||||

| Length ( mm ) | 2960 | 3700 | 3700 | 3700 | 3700 |

| Width ( mm ) | 1350 | 1790 | 1790 | 1790 | 1790 |

| Height ( mm ) | 1420 | 1900 | 1900 | 1900 | 1900 |

| Weight ( kg ) | 750 | 1650 | 1650 | 1650 | 1650 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY120-14 | EUY150-15 | EUY160-17 | EUY200-10 | EUY220-8* | EUY180-19 | EUY310-25 | EUY390-25* | EUY390-30 | EUY340-34 |

| Working Pressure, bar ( psi ) | 14 (205) | 15 (220) | 17 (250) | 10/17 (150/250) | 8/10 (115/150) | 19 (275) | 25.....18 (360.....260) |

25.....15 (360.....220) |

30.....20 (435.....290) |

34.....20 (493.....290) |

| Flow, I/s | cfm | m3/min | 200|424|12 | 250|530|15 | 267|565|16 | (333|706|20)/ (267|565|16) |

(367|777|22)/ (333|706|20) |

300|635|18 | (467|988|28) (517|1094|31) |

(583|1235|35) (650|1377|39) |

(583|1235|35) (650|1377|39) |

(533|1130|32) (567|1200|34) |

| Noise Sound Level ( at 7m distance , dBA ) | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 |

| Fuel tank capacity ( L ) | 180 | 250 | 250 | 250 | 250 | 300 | 500 | 550 | 710 | 710 |

| Compressor Oil Capacity ( L ) | 23 | 32 | 32 | 32 | 55 | 55 | 75 | 105 | 105 | 105 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/3 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Engine | ||||||||||

| Engine Maker | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | YC6J175-H301 | YC6A205-H300 | YC6A240-H301 | YC6A240-H301 | YC6A240-H301 | YC6A260-H300 | YC6MK400-H300 | YC6K510-KT30 | YC6K560-KT30 | YC6K560-KT30 |

| Engine Power ( Kw ) | 129 | 151 | 176 | 176 | 176 | 191 | 295 | 375 | 412 | 412 |

| Norminal Engine Speed ( rpm ) | 2300 | 2050 | 1950 | 2100/1800 | 2100/1800 | 1900 | 1750.....1900 | 1500.....1750 | 1500.....1750 | 1600.....1750 |

| Unloading Engine Speed ( rpm ) | 1400 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 2680 | 2680 | 2680 | 2680 | 2880 | 3985 | 4336 | 4336 | 4336 |

| Width ( mm ) | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 | 1800 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1637 | 1637 | 1637 | 1920 | 1920 | 1920 | 2200 | 2290 | 2290 | 2290 |

| Weight ( kg ) | 2050 | 2350 | 2350 | 2380 | 2380 | 3000 | 4550 | 4770 | 4770 | 4770 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4322 | 4322 | 4322 | 4322 | 4322 | 4341 | 5260 | 5590 | 5590 | 5590 |

| Width ( mm ) | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 | 2040 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1980 | 1980 | 1980 | 2270 | 2270 | 2270 | 2630 | 2660 | 2660 | 2660 |

| Weight ( kg ) | 2250 | 2550 | 2550 | 2685 | 2685 | 3330 | 5150 | 5270 | 5270 | 5270 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY100D-7 | EUY120D-13 | EUY130D-7 | EUY130D-10 | EUY165D-10 | EUY13D-13 | EUY203D-7 | EUY230D-8 | EUY210D-10 | EUY165D-14 |

| Working Pressure, bar ( psi ) | 7 (100) | 13 (185) | 7 (100) | 10 (150) | 10 (150) | 13 (185) | 7 (100) | 8 (115) | 10 (150) | 14 (205) |

| Flow, I/s | cfm | m3/min | 167|353|10 | 183|388|11 | 217|459|13 | 217|459|13 | 275|582|16.5 | 225|477|13.5 | 338|717|20.5 | 383|812|23 | 350|741|21 | 275|582|16.5 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 |

| Compressor Oil Capacity ( L ) | 20 | 28 | 28 | 28 | 55 | 55 | 55 | 55 | 55 | 55 |

| Outlet Valves ( qty x size ) | 1xG1 1/2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 55 | 90 | 75 | 90 | 110 | 110 | 110 | 132 | 132 | 132 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.9 | 0.88 | 0.9 | 0.88 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2235 | 2200 | 2200 | 2200 | 2680 | 2680 | 2680 | 2680 | 2680 | 2680 |

| Width ( mm ) | 1300 | 1170 | 1170 | 1170 | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 |

| Height ( mm ) | 1623 | 1400 | 1400 | 1400 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Weight ( kg ) | 1520 | 1440 | 1340 | 1440 | 2285 | 2285 | 2285 | 2285 | 2285 | 2285 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 3651 | 3840 | 3840 | 3840 | 4232 | 4232 | 4232 | 4232 | 4232 | 4232 |

| Width ( mm ) | 1790 | 1680 | 1680 | 1680 | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 |

| Height ( mm ) | 1850 | 1740 | 1740 | 1740 | 2170 | 2170 | 2170 | 2170 | 2170 | 2170 |

| Weight ( kg ) | 1700 | 1640 | 1540 | 1640 | 2590 | 2590 | 2590 | 2590 | 2590 | 2590 |

| MODEL | EUY150D-16 | EUY170D-17 | EUY250D-10 | EUY210D-14 | EUY280D-8.5 | EUY280D-10 | EUY238D-14 | EUY220D-21 | EUY250D-21 | EUY290D-21 |

|---|---|---|---|---|---|---|---|---|---|---|

| Working Pressure, bar ( psi ) | 16 (230) | 17 (250) | 10 (150) | 14 (205) | 8.5 (125) | 10 ( 150) | 14 (205) | 21 (305) | 22 (305) | 23 (305) |

| Flow, I/s | cfm | m3/min | 250|530|15 | 283|600|17 | 417|883|25 | 350|741|21 | 467|988|28 | 467|988|28 | 397|840|23.5 | 367|777|22 | 417|883|25 | 483|1024|29 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 78+3 | 78+3 | 78+3 |

| Compressor Oil Capacity ( L ) | 55 | 61 | 65 | 65 | 65 | 65 | 65 | 92 | 92 | 92 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 132 | 160 | 160 | 160 | 160 | 180 | 180 | 200 | 220 | 250 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.9 | 0.9 | 0.9 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 3280 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 |

| Width ( mm ) | 1660 | 1670 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Height ( mm ) | 1800 | 1870 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 |

| Weight ( kg ) | 2285 | 2850 | 3900 | 3900 | 3900 | 4000 | 4000 | 4100 | 4250 | 4300 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4232 | 4550 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 |

| Width ( mm ) | 1950 | 1770 | 1800 | 1800 | 1800 | 1800 | 1800 | 2040 | 2040 | 2040 |

| Height ( mm ) | 2170 | 2230 | 2590 | 2590 | 2590 | 2590 | 2590 | 2630 | 2630 | 2630 |

| Weight ( kg ) | 2590 | 2460 | 4500 | 4500 | 4500 | 4600 | 4600 | 4700 | 4850 | 4900 |

Ground Engineering Drilling

High Perfomance, Simple Maintenance Electrical Driven

EUROAIR Diesel Portable Compressor

Latest Screw Element Technology

The asymmetric rotors allow for increased efficiency. In addition, a low rotor speed and few moving parts minimize wear and tear for reliable performance and a long service life.

Clean Intake Air

A high performance two-stage air intage filter prevents dust and dirt particles from entering the engine and compressor. A service indicator on the filter tells you when it needs replacing.

Reputable Engine Brands

Every model has a carefully selected engine from a well-know and respected partner. All componets are protected inside the corrosion treated weatherproof hood

Efficient Fuel Filter

High – efficiency multi-step fuel filtration with water separator isolates and traps contaminants

Large Cooling Surface

Allowing optimal, intense use in hightemperature environments, wih working temperature up to 50C.

Fully Automatic Step-Less Speed Regulator

The in-house design controller together with the regulating system controls the engine speed to meet all customer’s needs, while keeping fuel consumption low.

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Pantented Powerxpert

The XC2003 controller features a very fast response curve, PowerXpert can instantly increase the rpm of the engine to achieve the maximum flow, while regulating the engine power curve at any specific pressure to allow more flow, faster flushing and increased drilling capacity.

Large Cooling Surface

Allowing optimal, intense use in high-temperature environments, with working temperatures up to 50C.

Depandable Gear Driven

Providing high transmission efficiency. Also minimizes any issues with the axles not aligning.

Heavy Duty Motor

The motor implements IEC standard, under protection class IP54. Making it suitable for high dust, non-stop working conditions

Union Control

Thanks to the CS6000 controller, customers can easily parallel two to six compressors to work together in harmony. This provides much greater flow and minimizes the effect of pressure drop.

Clean Intake Air

A high performance two-stage air intake filter prevents dust and dirt particles from entering the compressor. A service indicator on the filter tells you when it needs replacing.

Smart Control System

The CS6000 controllers have LCD display, good stability, and providing the full control of machine; multiplied languages selection.

Flexiable Coupling

The KTR coupling with elastic spider effectively reduces the effects of vibration and ensures higher reliability

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Technical Data

EUROAIR Diesel Portable Compressor

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | |||||

|---|---|---|---|---|---|

| MODEL | EUY050-7 | EUY085-14 | EUY100-10 | EUY100-12 | EUY120-7 |

| Working Pressure, bar ( psi ) | 7 (100) | 14 (205) | 10 (150) | 12 (175) | 7 (100) |

| Flow, I/s | cfm | m3/min | 83|177|5 | 142|300|8.5 | 167|353|10 | 167|353|10 | 200|424|12 |

| Noise Sound Level ( at 7m distance , dBA ) | 70+3 | 81+3 | 81+3 | 81+3 | 81+3 |

| Fuel tank capacity ( L ) | 67 | 120 | 120 | 120 | 120 |

| Compressor Oil Capacity ( L ) | 8 | 26 | 26 | 26 | 26 |

| Outlet Valves ( qty x size ) | 3xG3/4 | 1xG3/4 1xG1 1/2 | |||

| Engine | |||||

| Engine Maker | Kubota | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | V1505T | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 |

| Engine Power ( Kw ) | 33 | 96 | 96 | 96 | 96 |

| Norminal Engine Speed ( rpm ) | 2950 | 2300 | 2300 | 2300 | 2300 |

| Unloading Engine Speed ( rpm ) | 1950 | 1400 | 1400 | 1400 | 1400 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | |||||

| Box Mounted | |||||

| Length ( mm ) | 1940 | 2350 | 2350 | 2350 | 2350 |

| Width ( mm ) | 1200 | 1300 | 1300 | 1300 | 1300 |

| Height ( mm ) | 1240 | 1550 | 1550 | 1550 | 1550 |

| Weight ( kg ) | 650 | 1470 | 1470 | 1470 | 1470 |

| With Undercarriage ( adjustable tow bar horizontally ) | |||||

| Length ( mm ) | 2960 | 3700 | 3700 | 3700 | 3700 |

| Width ( mm ) | 1350 | 1790 | 1790 | 1790 | 1790 |

| Height ( mm ) | 1420 | 1900 | 1900 | 1900 | 1900 |

| Weight ( kg ) | 750 | 1650 | 1650 | 1650 | 1650 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY120-14 | EUY150-15 | EUY160-17 | EUY200-10 | EUY220-8* | EUY180-19 | EUY310-25 | EUY390-25* | EUY390-30 | EUY340-34 |

| Working Pressure, bar ( psi ) | 14 (205) | 15 (220) | 17 (250) | 10/17 (150/250) | 8/10 (115/150) | 19 (275) | 25.....18 (360.....260) |

25.....15 (360.....220) |

30.....20 (435.....290) |

34.....20 (493.....290) |

| Flow, I/s | cfm | m3/min | 200|424|12 | 250|530|15 | 267|565|16 | (333|706|20)/ (267|565|16) |

(367|777|22)/ (333|706|20) |

300|635|18 | (467|988|28) (517|1094|31) |

(583|1235|35) (650|1377|39) |

(583|1235|35) (650|1377|39) |

(533|1130|32) (567|1200|34) |

| Noise Sound Level ( at 7m distance , dBA ) | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 |

| Fuel tank capacity ( L ) | 180 | 250 | 250 | 250 | 250 | 300 | 500 | 550 | 710 | 710 |

| Compressor Oil Capacity ( L ) | 23 | 32 | 32 | 32 | 55 | 55 | 75 | 105 | 105 | 105 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/3 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Engine | ||||||||||

| Engine Maker | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | YC6J175-H301 | YC6A205-H300 | YC6A240-H301 | YC6A240-H301 | YC6A240-H301 | YC6A260-H300 | YC6MK400-H300 | YC6K510-KT30 | YC6K560-KT30 | YC6K560-KT30 |

| Engine Power ( Kw ) | 129 | 151 | 176 | 176 | 176 | 191 | 295 | 375 | 412 | 412 |

| Norminal Engine Speed ( rpm ) | 2300 | 2050 | 1950 | 2100/1800 | 2100/1800 | 1900 | 1750.....1900 | 1500.....1750 | 1500.....1750 | 1600.....1750 |

| Unloading Engine Speed ( rpm ) | 1400 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 2680 | 2680 | 2680 | 2680 | 2880 | 3985 | 4336 | 4336 | 4336 |

| Width ( mm ) | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 | 1800 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1637 | 1637 | 1637 | 1920 | 1920 | 1920 | 2200 | 2290 | 2290 | 2290 |

| Weight ( kg ) | 2050 | 2350 | 2350 | 2380 | 2380 | 3000 | 4550 | 4770 | 4770 | 4770 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4322 | 4322 | 4322 | 4322 | 4322 | 4341 | 5260 | 5590 | 5590 | 5590 |

| Width ( mm ) | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 | 2040 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1980 | 1980 | 1980 | 2270 | 2270 | 2270 | 2630 | 2660 | 2660 | 2660 |

| Weight ( kg ) | 2250 | 2550 | 2550 | 2685 | 2685 | 3330 | 5150 | 5270 | 5270 | 5270 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY100D-7 | EUY120D-13 | EUY130D-7 | EUY130D-10 | EUY165D-10 | EUY13D-13 | EUY203D-7 | EUY230D-8 | EUY210D-10 | EUY165D-14 |

| Working Pressure, bar ( psi ) | 7 (100) | 13 (185) | 7 (100) | 10 (150) | 10 (150) | 13 (185) | 7 (100) | 8 (115) | 10 (150) | 14 (205) |

| Flow, I/s | cfm | m3/min | 167|353|10 | 183|388|11 | 217|459|13 | 217|459|13 | 275|582|16.5 | 225|477|13.5 | 338|717|20.5 | 383|812|23 | 350|741|21 | 275|582|16.5 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 |

| Compressor Oil Capacity ( L ) | 20 | 28 | 28 | 28 | 55 | 55 | 55 | 55 | 55 | 55 |

| Outlet Valves ( qty x size ) | 1xG1 1/2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 55 | 90 | 75 | 90 | 110 | 110 | 110 | 132 | 132 | 132 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.9 | 0.88 | 0.9 | 0.88 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2235 | 2200 | 2200 | 2200 | 2680 | 2680 | 2680 | 2680 | 2680 | 2680 |

| Width ( mm ) | 1300 | 1170 | 1170 | 1170 | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 |

| Height ( mm ) | 1623 | 1400 | 1400 | 1400 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Weight ( kg ) | 1520 | 1440 | 1340 | 1440 | 2285 | 2285 | 2285 | 2285 | 2285 | 2285 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 3651 | 3840 | 3840 | 3840 | 4232 | 4232 | 4232 | 4232 | 4232 | 4232 |

| Width ( mm ) | 1790 | 1680 | 1680 | 1680 | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 |

| Height ( mm ) | 1850 | 1740 | 1740 | 1740 | 2170 | 2170 | 2170 | 2170 | 2170 | 2170 |

| Weight ( kg ) | 1700 | 1640 | 1540 | 1640 | 2590 | 2590 | 2590 | 2590 | 2590 | 2590 |

| MODEL | EUY150D-16 | EUY170D-17 | EUY250D-10 | EUY210D-14 | EUY280D-8.5 | EUY280D-10 | EUY238D-14 | EUY220D-21 | EUY250D-21 | EUY290D-21 |

|---|---|---|---|---|---|---|---|---|---|---|

| Working Pressure, bar ( psi ) | 16 (230) | 17 (250) | 10 (150) | 14 (205) | 8.5 (125) | 10 ( 150) | 14 (205) | 21 (305) | 22 (305) | 23 (305) |

| Flow, I/s | cfm | m3/min | 250|530|15 | 283|600|17 | 417|883|25 | 350|741|21 | 467|988|28 | 467|988|28 | 397|840|23.5 | 367|777|22 | 417|883|25 | 483|1024|29 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 78+3 | 78+3 | 78+3 |

| Compressor Oil Capacity ( L ) | 55 | 61 | 65 | 65 | 65 | 65 | 65 | 92 | 92 | 92 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 132 | 160 | 160 | 160 | 160 | 180 | 180 | 200 | 220 | 250 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.9 | 0.9 | 0.9 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 3280 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 |

| Width ( mm ) | 1660 | 1670 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Height ( mm ) | 1800 | 1870 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 |

| Weight ( kg ) | 2285 | 2850 | 3900 | 3900 | 3900 | 4000 | 4000 | 4100 | 4250 | 4300 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4232 | 4550 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 |

| Width ( mm ) | 1950 | 1770 | 1800 | 1800 | 1800 | 1800 | 1800 | 2040 | 2040 | 2040 |

| Height ( mm ) | 2170 | 2230 | 2590 | 2590 | 2590 | 2590 | 2590 | 2630 | 2630 | 2630 |

| Weight ( kg ) | 2590 | 2460 | 4500 | 4500 | 4500 | 4600 | 4600 | 4700 | 4850 | 4900 |

HDR SERIES REFRIGERATED AIR DRYER

EUROAIR HDR SERIES REFRIGERATED AIR DRYER

The cost will be increased because of the bad quality compressed air

If acidic sludge entering air line, the caused problem will come soon. Below are some common problems:

- Damage of pneumatic tools and equipment more frequently, life reduction.

- Finished production and other materials that will expose to air will be damaged or quality reduction

- Corroded air line will result in air leaking, wasting of compressed air and energy.

- In fact, a leak with thickness 3 mm will cause 3.7 kW energy consumption, which means there will be extra energy cost every year.

The damage of the unprocessed compressed air

-

Compressed air is an important driving force which is widely used in various industrial fields. After the air around us is compressed,

a sharp rise in the number of water vapor and dust contained in unit volume. -

Meanwhile the water vapor and oil mist condense liquid drops during compressing process,

then mixing with dusts in high concentration, forming mostly acidic sludge. -

If there is no air after treatment equipment, these acidic sludge will enter the air line, corrode pipeline material,

destroy pneumatic tools, equipment, and ultimately resulting in lower-quality product, production stagnated, costs rising,

health and safety at risk.

The damage of the unprocessed compressed air

- Air dryer is a durable and low energy consumed air solution.

-

Drying process on compressed air is needed in order to prevent the condensed water precipitation

and the followed corrosion and equipment damage.

Sunfilter series air dry can remove the water from the compressed air, which remove the biggest damage on air pipe system. - More filter, complete the installation of equipment.

-

More filter in the compressed air system will further improve the quality of air,

reducing the possibility of damage of pneumatic tools and equipment, enhance the quality of finished production.

Technical Specifications

EUROAIR Refrigerated Air Dryer

| HDR SERIES REFRIGERATED AIR DRYER | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Capacity Nm3/Min | Nominal Power Kw | Power Supply V/Ph/Hz | Air Connections | Dimension (mm) | Weight Kg | ||

| L | W | H | ||||||

| HDR-10HP | 1.2 | 0.85 | 220/1/50 | Rc1" | 630 | 450 | 640 | 50 |

| HDR-20HP | 2.4 | 1 | 220/1/50 | Rc1" | 700 | 450 | 830 | 80 |

| HDR-30HP | 3.8 | 1.25 | 220/1/50 | Rc1.5" | 850 | 500 | 920 | 105 |

| HDR-50HP | 6.4 | 1.5 | 220/1/50 | Rc1.5" | 880 | 550 | 1020 | 150 |

| HDR-60HP | 8 | 1.8 | 220/1/50 | Rc1.5" | 880 | 550 | 1020 | 160 |

| HDR-75HP | 10.5 | 2.5 | 380/3/50 | Rc2" | 1180 | 670 | 1080 | 240 |

| HDR-100HP | 13.5 | 2.5 | 380/3/50 | Rc2" | 1180 | 670 | 1080 | 260 |

| HDR-125HP | 18 | 3 | 380/3/50 | DN65 | 1360 | 710 | 1220 | 310 |

| HDR-150HP | 25 | 4 | 380/3/50 | DN80 | 1360 | 710 | 1220 | 400 |

| HDR-200HP | 28 | 4.5 | 380/3/50 | DN80 | 1650 | 750 | 1290 | 450 |

| HDR-300HP | 35 | 6.5 | 380/3/50 | DN100 | 1670 | 750 | 1575 | 780 |

| HDR-350HP | 45 | 8.8 | 380/3/50 | DN100 | 2000 | 950 | 1740 | 820 |

| HDR-400HP | 55 | 10.2 | 380/3/50 | DN125 | 2350 | 1050 | 1910 | 900 |

| HDR-450HP | 65 | 13 | 380/3/50 | DN125 | 2550 | 1100 | 1940 | 1100 |

HEATLESS PURGE DESICCANT AIR DRYER

Product Advantages

-

Automatic Control System

Automatic control system and alarm device, ensure the safety and reliability.

-

Air Controlling Dust Filter

Air controlling dust filter prevents the dust from air controlling components, lower the valves failure rate.

-

Silencer

New design silencer is made from heat-resistant hyperfine sound-absorbing glass, the noise level ≤72dB(A)

-

Stainless Steel Disperser

Stainless steel disperser stabilizes, disperses and filters the air flow.

-

High Quality Desiccant

High quality desiccant activated aluminum or molecular sieve, long service life.

Technical Specifications

EUROAIR Heatless Purge Dessicant Air Dryer

| Technical Specifications HEATLESS PURGE DESICCANT AIR DRYER | |||||||

|---|---|---|---|---|---|---|---|

| Type | Capacity ( Nm3/min ) |

Heater Power (kW) |

Air Inlet/Outlet Pipa Diameter |

Dimension | Weight (kg) |

||

| L | W | H | |||||

| HDR-10XF | 1.2 | 15 | ZG1 | 800 | 400 | 1376 | 120 |

| HDR-20XF | 2.4 | 15 | ZG1 | 800 | 400 | 1476 | 180 |

| HDR-30XF | 3.8 | 15 | ZG1.5 | 1000 | 450 | 1600 | 270 |

| HDR-50XF | 5.5 | 15 | ZG1.5 | 1000 | 450 | 1890 | 300 |

| HDR-60XF | 6.5 | 3 | ZG1.5 | 1200 | 500 | 1950 | 400 |

| HDR-75XF | 8.5 | 3 | ZG1.5 | 1400 | 600 | 2000 | 510 |

| HDR-100XF | 10.7 | 45 | ZG2 | 1400 | 600 | 2090 | 700 |

| HDR-150XF | 13.5 | 45 | ZG2 | 1400 | 600 | 2140 | 740 |

| HDR-200XF | 18 | 45 | DN65 | 1400 | 600 | 2200 | 780 |

| HDR-250XF | 25 | 6 | DN80 | 1670 | 650 | 2435 | 1180 |

| HDR-300XF | 35 | 8 | DN100 | 1670 | 650 | 2566 | 1760 |

| HDR-350XF | 45 | 8 | DN100 | 1670 | 750 | 2700 | 2200 |

| HDR-400XF | 55 | 15 | DN125 | 1800 | 750 | 2755 | 2600 |

| HDR-450XF | 65 | 15 | DN125 | 1900 | 700 | 3070 | 3100 |

| HDR-500XF | 85 | 20 | DN150 | 2620 | 1120 | 3070 | 4100 |

| HDR-550XF | 110 | 30 | DN150 | 3100 | 1650 | 3200 | 5200 |

| HDR-600XF | 160 | 50 | DN200 | 3240 | 1770 | 3190 | 6000 |

High Pressure Drilling

$20,000.00

High Perfomance, Simple Maintenance Electrical Driven

EUROAIR Diesel Portable Compressor

Latest Screw Element Technology

The asymmetric rotors allow for increased efficiency. In addition, a low rotor speed and few moving parts minimize wear and tear for reliable performance and a long service life.

Clean Intake Air

A high performance two-stage air intage filter prevents dust and dirt particles from entering the engine and compressor. A service indicator on the filter tells you when it needs replacing.

Reputable Engine Brands

Every model has a carefully selected engine from a well-know and respected partner. All componets are protected inside the corrosion treated weatherproof hood

Efficient Fuel Filter

High – efficiency multi-step fuel filtration with water separator isolates and traps contaminants

Large Cooling Surface

Allowing optimal, intense use in hightemperature environments, wih working temperature up to 50C.

Fully Automatic Step-Less Speed Regulator

The in-house design controller together with the regulating system controls the engine speed to meet all customer’s needs, while keeping fuel consumption low.

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Pantented Powerxpert

The XC2003 controller features a very fast response curve, PowerXpert can instantly increase the rpm of the engine to achieve the maximum flow, while regulating the engine power curve at any specific pressure to allow more flow, faster flushing and increased drilling capacity.

Large Cooling Surface

Allowing optimal, intense use in high-temperature environments, with working temperatures up to 50C.

Depandable Gear Driven

Providing high transmission efficiency. Also minimizes any issues with the axles not aligning.

Heavy Duty Motor

The motor implements IEC standard, under protection class IP54. Making it suitable for high dust, non-stop working conditions

Union Control

Thanks to the CS6000 controller, customers can easily parallel two to six compressors to work together in harmony. This provides much greater flow and minimizes the effect of pressure drop.

Clean Intake Air

A high performance two-stage air intake filter prevents dust and dirt particles from entering the compressor. A service indicator on the filter tells you when it needs replacing.

Smart Control System

The CS6000 controllers have LCD display, good stability, and providing the full control of machine; multiplied languages selection.

Flexiable Coupling

The KTR coupling with elastic spider effectively reduces the effects of vibration and ensures higher reliability

Easy To Transport

Robust undercarriage design with torsional spring to ensure easy, safe transportability.

Technical Data

EUROAIR Diesel Portable Compressor

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | |||||

|---|---|---|---|---|---|

| MODEL | EUY050-7 | EUY085-14 | EUY100-10 | EUY100-12 | EUY120-7 |

| Working Pressure, bar ( psi ) | 7 (100) | 14 (205) | 10 (150) | 12 (175) | 7 (100) |

| Flow, I/s | cfm | m3/min | 83|177|5 | 142|300|8.5 | 167|353|10 | 167|353|10 | 200|424|12 |

| Noise Sound Level ( at 7m distance , dBA ) | 70+3 | 81+3 | 81+3 | 81+3 | 81+3 |

| Fuel tank capacity ( L ) | 67 | 120 | 120 | 120 | 120 |

| Compressor Oil Capacity ( L ) | 8 | 26 | 26 | 26 | 26 |

| Outlet Valves ( qty x size ) | 3xG3/4 | 1xG3/4 1xG1 1/2 | |||

| Engine | |||||

| Engine Maker | Kubota | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | V1505T | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 | YC4A130-H311 |

| Engine Power ( Kw ) | 33 | 96 | 96 | 96 | 96 |

| Norminal Engine Speed ( rpm ) | 2950 | 2300 | 2300 | 2300 | 2300 |

| Unloading Engine Speed ( rpm ) | 1950 | 1400 | 1400 | 1400 | 1400 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | |||||

| Box Mounted | |||||

| Length ( mm ) | 1940 | 2350 | 2350 | 2350 | 2350 |

| Width ( mm ) | 1200 | 1300 | 1300 | 1300 | 1300 |

| Height ( mm ) | 1240 | 1550 | 1550 | 1550 | 1550 |

| Weight ( kg ) | 650 | 1470 | 1470 | 1470 | 1470 |

| With Undercarriage ( adjustable tow bar horizontally ) | |||||

| Length ( mm ) | 2960 | 3700 | 3700 | 3700 | 3700 |

| Width ( mm ) | 1350 | 1790 | 1790 | 1790 | 1790 |

| Height ( mm ) | 1420 | 1900 | 1900 | 1900 | 1900 |

| Weight ( kg ) | 750 | 1650 | 1650 | 1650 | 1650 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY120-14 | EUY150-15 | EUY160-17 | EUY200-10 | EUY220-8* | EUY180-19 | EUY310-25 | EUY390-25* | EUY390-30 | EUY340-34 |

| Working Pressure, bar ( psi ) | 14 (205) | 15 (220) | 17 (250) | 10/17 (150/250) | 8/10 (115/150) | 19 (275) | 25.....18 (360.....260) |

25.....15 (360.....220) |

30.....20 (435.....290) |

34.....20 (493.....290) |

| Flow, I/s | cfm | m3/min | 200|424|12 | 250|530|15 | 267|565|16 | (333|706|20)/ (267|565|16) |

(367|777|22)/ (333|706|20) |

300|635|18 | (467|988|28) (517|1094|31) |

(583|1235|35) (650|1377|39) |

(583|1235|35) (650|1377|39) |

(533|1130|32) (567|1200|34) |

| Noise Sound Level ( at 7m distance , dBA ) | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 | 83+3 |

| Fuel tank capacity ( L ) | 180 | 250 | 250 | 250 | 250 | 300 | 500 | 550 | 710 | 710 |

| Compressor Oil Capacity ( L ) | 23 | 32 | 32 | 32 | 55 | 55 | 75 | 105 | 105 | 105 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/3 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Engine | ||||||||||

| Engine Maker | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai | Yuchai |

| Engine Model | YC6J175-H301 | YC6A205-H300 | YC6A240-H301 | YC6A240-H301 | YC6A240-H301 | YC6A260-H300 | YC6MK400-H300 | YC6K510-KT30 | YC6K560-KT30 | YC6K560-KT30 |

| Engine Power ( Kw ) | 129 | 151 | 176 | 176 | 176 | 191 | 295 | 375 | 412 | 412 |

| Norminal Engine Speed ( rpm ) | 2300 | 2050 | 1950 | 2100/1800 | 2100/1800 | 1900 | 1750.....1900 | 1500.....1750 | 1500.....1750 | 1600.....1750 |

| Unloading Engine Speed ( rpm ) | 1400 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 |

| Engine Inspiration | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger | Turbocharger |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 2680 | 2680 | 2680 | 2680 | 2880 | 3985 | 4336 | 4336 | 4336 |

| Width ( mm ) | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 | 1800 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1637 | 1637 | 1637 | 1920 | 1920 | 1920 | 2200 | 2290 | 2290 | 2290 |

| Weight ( kg ) | 2050 | 2350 | 2350 | 2380 | 2380 | 3000 | 4550 | 4770 | 4770 | 4770 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4322 | 4322 | 4322 | 4322 | 4322 | 4341 | 5260 | 5590 | 5590 | 5590 |

| Width ( mm ) | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 | 2040 | 2100 | 2100 | 2100 |

| Height ( mm ) | 1980 | 1980 | 1980 | 2270 | 2270 | 2270 | 2630 | 2660 | 2660 | 2660 |

| Weight ( kg ) | 2250 | 2550 | 2550 | 2685 | 2685 | 3330 | 5150 | 5270 | 5270 | 5270 |

| TECHNICAL PARAMETER DIESEL PORTABLE COMPRESSOR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | EUY100D-7 | EUY120D-13 | EUY130D-7 | EUY130D-10 | EUY165D-10 | EUY13D-13 | EUY203D-7 | EUY230D-8 | EUY210D-10 | EUY165D-14 |

| Working Pressure, bar ( psi ) | 7 (100) | 13 (185) | 7 (100) | 10 (150) | 10 (150) | 13 (185) | 7 (100) | 8 (115) | 10 (150) | 14 (205) |

| Flow, I/s | cfm | m3/min | 167|353|10 | 183|388|11 | 217|459|13 | 217|459|13 | 275|582|16.5 | 225|477|13.5 | 338|717|20.5 | 383|812|23 | 350|741|21 | 275|582|16.5 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 | 73+3 |

| Compressor Oil Capacity ( L ) | 20 | 28 | 28 | 28 | 55 | 55 | 55 | 55 | 55 | 55 |

| Outlet Valves ( qty x size ) | 1xG1 1/2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 |

1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 55 | 90 | 75 | 90 | 110 | 110 | 110 | 132 | 132 | 132 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.9 | 0.88 | 0.9 | 0.88 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2235 | 2200 | 2200 | 2200 | 2680 | 2680 | 2680 | 2680 | 2680 | 2680 |

| Width ( mm ) | 1300 | 1170 | 1170 | 1170 | 1660 | 1660 | 1660 | 1660 | 1660 | 1660 |

| Height ( mm ) | 1623 | 1400 | 1400 | 1400 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Weight ( kg ) | 1520 | 1440 | 1340 | 1440 | 2285 | 2285 | 2285 | 2285 | 2285 | 2285 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 3651 | 3840 | 3840 | 3840 | 4232 | 4232 | 4232 | 4232 | 4232 | 4232 |

| Width ( mm ) | 1790 | 1680 | 1680 | 1680 | 1950 | 1950 | 1950 | 1950 | 1950 | 1950 |

| Height ( mm ) | 1850 | 1740 | 1740 | 1740 | 2170 | 2170 | 2170 | 2170 | 2170 | 2170 |

| Weight ( kg ) | 1700 | 1640 | 1540 | 1640 | 2590 | 2590 | 2590 | 2590 | 2590 | 2590 |

| MODEL | EUY150D-16 | EUY170D-17 | EUY250D-10 | EUY210D-14 | EUY280D-8.5 | EUY280D-10 | EUY238D-14 | EUY220D-21 | EUY250D-21 | EUY290D-21 |

|---|---|---|---|---|---|---|---|---|---|---|

| Working Pressure, bar ( psi ) | 16 (230) | 17 (250) | 10 (150) | 14 (205) | 8.5 (125) | 10 ( 150) | 14 (205) | 21 (305) | 22 (305) | 23 (305) |

| Flow, I/s | cfm | m3/min | 250|530|15 | 283|600|17 | 417|883|25 | 350|741|21 | 467|988|28 | 467|988|28 | 397|840|23.5 | 367|777|22 | 417|883|25 | 483|1024|29 |

| Noise Sound Level ( at 7m distance , dBA ) | 73+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 75+3 | 78+3 | 78+3 | 78+3 |

| Compressor Oil Capacity ( L ) | 55 | 61 | 65 | 65 | 65 | 65 | 65 | 92 | 92 | 92 |

| Outlet Valves ( qty x size ) | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 | 1xG2 1xG3/4 |

| Motor Power ( Kw ) | 132 | 160 | 160 | 160 | 160 | 180 | 180 | 200 | 220 | 250 |

| Service Factor | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 |

| Voltage ( v ) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| Power Factor | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.9 | 0.9 | 0.9 |

| Motor Speed (rpm) | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 | 2970 |

| Starting Method | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta | Star Delta |

| Protection Class | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F | IP54/F |

| Dimension & Weight | ||||||||||

| Box Mounted | ||||||||||

| Length ( mm ) | 2680 | 3280 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 | 3985 |

| Width ( mm ) | 1660 | 1670 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Height ( mm ) | 1800 | 1870 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 |

| Weight ( kg ) | 2285 | 2850 | 3900 | 3900 | 3900 | 4000 | 4000 | 4100 | 4250 | 4300 |

| With Undercarriage ( adjustable tow bar horizontally ) | ||||||||||

| Length ( mm ) | 4232 | 4550 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 | 5260 |

| Width ( mm ) | 1950 | 1770 | 1800 | 1800 | 1800 | 1800 | 1800 | 2040 | 2040 | 2040 |

| Height ( mm ) | 2170 | 2230 | 2590 | 2590 | 2590 | 2590 | 2590 | 2630 | 2630 | 2630 |

| Weight ( kg ) | 2590 | 2460 | 4500 | 4500 | 4500 | 4600 | 4600 | 4700 | 4850 | 4900 |

Low Pressure Screw Air Compressor

Product Feature

Big diameter rotors with low rotation speed can achieve higher efficiency, lower noise level, less vibration and consume less power.Specially designed inlet air filter that prevents dirt and airborne contaminants from reaching compressor components and causing damage or premature wear.Large dimensions high efficiency oil separation system to ensure oil carryover in discharge compressed air less than 3 ppm.

-

More Energy Saving

Whether you are new investments, or replace the existing 0.7-0.8 Mpa air compressors, our low-pressure twin-screw compressor can save more electricity cost for you.

Technical Specifications

EUROAIR Low Pressure Screw Compressor

| Technical Specifications of Low Pressure Screw Air Compressor | |||||

|---|---|---|---|---|---|

| Model | Nominal Power ( kW ) |

Working Pressure ( bar ) |

Capacity FAD (m3/min) |

Discharge air pipe connection |

Dimension ( mm ) ( L x W x H ) |

| EKB15L-3 | 15 | 3 | 3.77 | DN40 | 1400 x 1000 x 1500 |

| EKB18L-3 | 18.5 | 3 | 4.8 | DN50 | 1650 x 1100 x 1650 |

| EKB22L-3 | 22 | 3 | 5.5 | DN50 | 1650 x 960 x 1650 |

| EKC30L-3 | 30 | 3 | 7.8 | DN65 | 1850 x 1300 x 1850 |

| EKC37L-3 | 37 | 3 | 10.0 | DN65 | 1850 x 1300 x 1850 |

| EKC45L-3 | 45 | 3 | 13.0 | DN80 | 2200 x 1350 x 1850 |

| EKD55L-3 | 55 | 3 | 16.0 | DN100 | 2790 x 1800 x 2050 |

| EKD75L-3 | 75 | 3 | 20.5 | DN100 | 2790 x 1800 x 2050 |

| EKE90L-3 | 90 | 3 | 28.0 | DN125 | 3590 x 2060 x 2300 |

| EKE110L-3 | 110 | 3 | 32.0 | DN150 | 3590 x 2060 x 2300 |

| EKE132L-3 | 132 | 3 | 41.0 | DN150 | 4050 x 2060 x 2300 |

| EKF160L-3 | 160 | 3 | 44.0 | DN150 | 4050 x 2060 x 2300 |

| EKF185L-3 | 185 | 3 | 49.5 | DN150 | 4250 x 2060 x 2300 |

| EKF200L-3 | 200 | 3 | 55.5 | DN200 | 4250 x 2060 x 2300 |

| EKF220L-3 | 220 | 3 | 60.5 | DN200 | 4550 x 2060 x 2300 |

| EKF250L-3 | 250 | 3 | 65.5 | DN200 | 4550 x 2060 x 2300 |

MICRO FILTERS LEVEL

Features

- Air filter with differential pressure indicator and sight glass

- Filter housing internal with anti-corrosion treatment

Benefits

- Higher efficiency and reliability of compressed air filtration

- Less prone to damage of equipment

- Higher cost-effectiveness

- Different filter elements for specific filtration demand

- Simple structure, low maintenance cost

Technical Specifications

EUROAIR Micro Filter

| MICRO FILTERS LEVEL | ||||||

|---|---|---|---|---|---|---|

| Type | Capacity ( Nm3/min ) |

Air Connection | Dimension | Weight (kg) |

||

| L | W | H | ||||

| HDR-K-10 | 1.2 | ZG1 | 105 | 76 | 250 | 2 |

| HDR-K-20 | 2.4 | ZG1 | 105 | 78 | 310 | 2 |

| HDR-K-30 | 3.8 | ZG1.5 | 137 | 99 | 400 | 2 |

| HDR-K-50 | 6.5 | ZG1.5 | 137 | 99 | 425 | 2 |

| HDR-K-60 | 8 | ZG1.5 | 137 | 99 | 620 | 3 |

| HDR-K-75 | 6 | ZG2 | 137 | 99 | 620 | 4 |

| HDR-K-75F | 10.7 | DN50 | 310 | 133 | 860 | 5 |

| HDR-K-100 | 14 | ZG2 | 135 | 108 | 750 | 25 |

| HDR-K-100F | 14 | DN50 | 310 | 133 | 860 | 10 |

| HDR-K-125 | 18 | ZG2.5 | 148 | 125 | 920 | 13 |

| HDR-K-125F | 18 | DN65 | 310 | 133 | 860 | 25 |

| HDR-K-150 | 22 | ZG2.5 | 148 | 125 | 920 | 14 |

| HDR-K-200 | 25 | DN80 | 379 | 133 | 1040 | 44 |

| HDR-K-250 | 28 | DN80 | 379 | 133 | 1140 | 52 |

| HDR-K-300 | 35 | DN100 | 465 | 219 | 1060 | 65 |

| HDR-K-350 | 45 | DN100 | 470 | 219 | 1060 | 68 |

| HDR-K-400 | 55 | DN125 | 513 | 273 | 1215 | 96 |

| HDR-K-450 | 65 | DN125 | 513 | 273 | 1215 | 96 |

| HDR-K-500 | 85 | DN150 | 615 | 325 | 1395 | 140 |

| HDR-K-600 | 110 | DN150 | 615 | 377 | 1300 | 145 |

| HDR-K-650 | 130 | DN150 | 615 | 416 | 1395 | 210 |

| HDR-K-700 | 150 | DN200 | 615 | 462 | 1470 | 220 |

| HDR-K-750 | 180 | DN200 | 615 | 462 | 1470 | 235 |

| HDR-K-800 | 200 | DN200 | 615 | 516 | 1504 | 240 |

IND

IND