ABOUT EUROAIR

ANEST IWATA joint-venture. 20 years of industry experience.

EUROAIR has been in the compressor business for decades, with a long history of experience in the air compressor field. As a professional manufacturer of compressor systems, EUROAIR is dedicated to supplying reliable, efficient and stable screw compressors. With a wide range of compressors from oil injected fixed-speed driven screw compressors, two stage variable-speed driven screw compressors, to diesel screw compressors, for customers. across the archipelago in all types of industrial applications, from manufacturing to construction to mining, we are here to increase efficiency, reduce energy consumption and reduce high production costs.

Reliable Component by Europe Technology

Low cost maintenance

Rapid Business Development

Extensive Cooperation Network

OUR PRODUCTS

We supply you with solutions, not just the products.

Industries Covered

We know that different industries have different requirements, so we offer the unique solution to meet your production demand. Click on any of industries below to discover our capabilities, and find out more about how we can help your business with our compressed air systems.

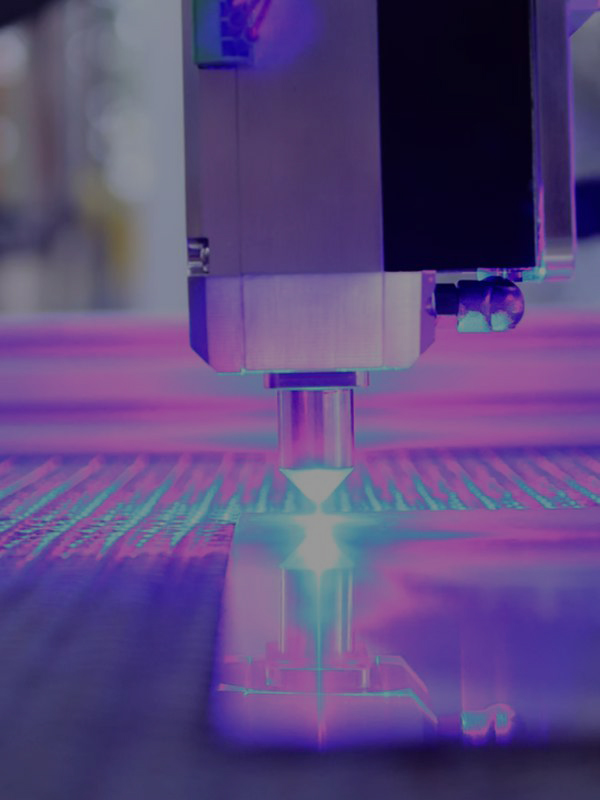

LASER CUTTING

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

PHARMACEUTICAL

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

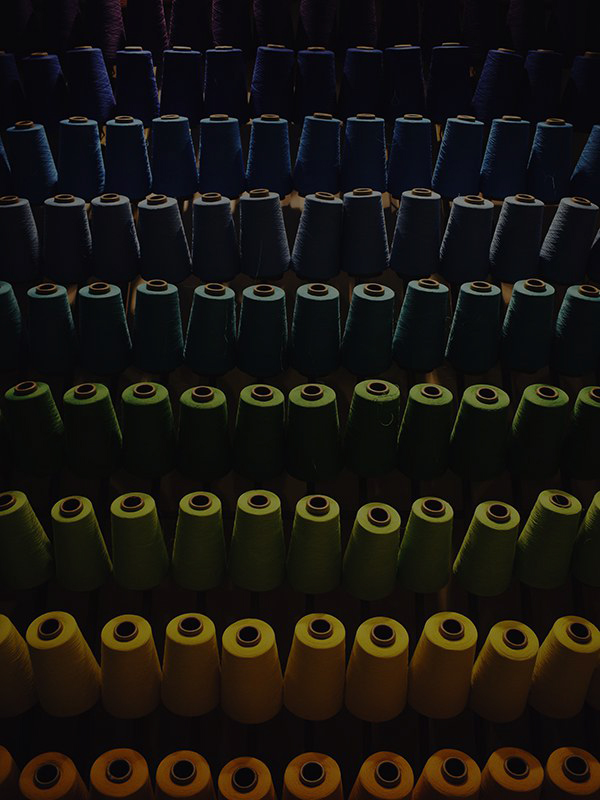

textile

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

MINING & GEOTHERMAL DRILLING

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

CHEMICAL

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

RUBBER & PLASTIC

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

FOOD & BEVERAGE

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

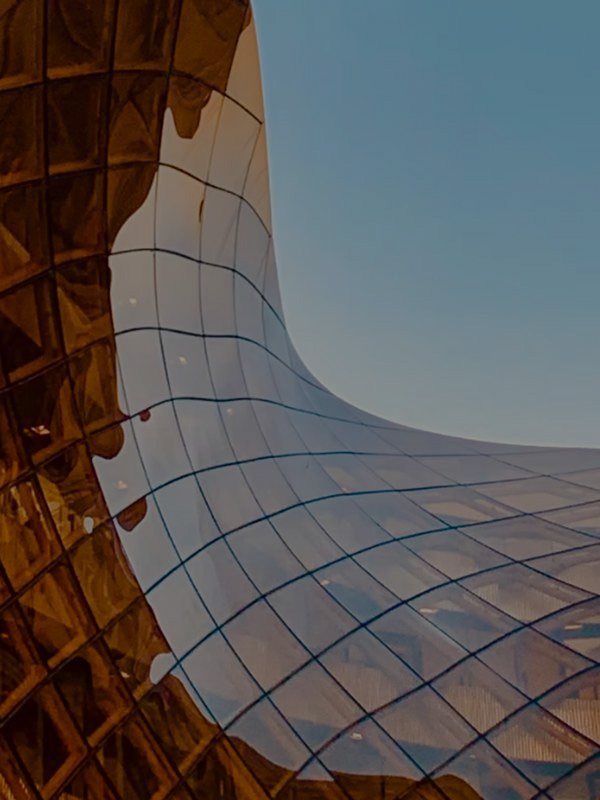

GLASS

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

Tetap Up to Date dengan

Berita Terbaru dari Kami!

CHEMICAL

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

RUBBER & PLASTIC

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

FOOD & BEVERAGE

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

GLASS

When it comes to laser cutting operations, large volumes of compressed air are required as a power source, the pressure needed is generally greater than 13kg. This enables the laser beam to irradiate the surface of workpiece to make it reach the melting point.

IND

IND